The food industry faces the challenge of making packaging and logistics processes flexible, safe and efficient. Traditional gripping systems have their limitations, while manual processes are costly, error-prone and burdensome. The UniGripper from Rivatec offers the solution: an intelligent vacuum flat gripper that automatically adapts to changing requirements, reduces set-up times by 50% and significantly optimises picking processes.

The UniGripper was developed in the mid-1990s to efficiently move glass packaging in jam production regardless of formats, fill levels or spacing. This flexibility remains the central feature of the system to this day and has been transferred to many industries.

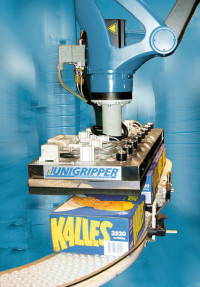

The food industry is increasingly relying on robot-assisted automation. This requires adaptable grippers that work safely and efficiently. With the UniGripper, Rivatec offers proven vacuum technology with intelligent valve control: The vacuum is only activated where products are located. This allows the gripper to automatically adapt to different shapes, sizes and packaging without the need for retooling. This saves energy, reduces costs and increases process reliability. The system is used for palletising and depalletising glass, cans or trays even in ATEX zones and confined installation spaces. A tool-free quick-change system reduces downtime and lowers personnel costs. Practical values show over 50% shorter set-up times.

Thanks to an increased gripping width of 50 mm and integrated sensor technology, even displaced products can be handled reliably. Entire containers or mixed layers can be moved simultaneously, reducing cycle times. Soft suction surfaces protect sensitive items, while optional clamps increase process reliability. The UniGripper integrates seamlessly into robot or gantry systems and is suitable for mixed pallets and flexible packaging units. Rivatec does not supply standard products, but designs tailor-made solutions from a quantity of 1 right up to cobot-supported variants for smaller businesses. The UniGripper LightWeight enables gentle handling of individual trays or cartons. Additional modules such as interlayer removers expand the range of possible applications. This makes the UniGripper more than just a gripper: It is an intelligent component for efficient, flexible material flows in automated processes.